' Experience Our Revolutionary Technology for Upgrading Lower Selection to Higher

by using Sellam Finishing Compacts, Wet Blue & Wet End Upgradation Products'

Solutions for India

Wet End Upgradation Products

Seltan CMZero formaldehyde high performance eco-friendly chrome syntan

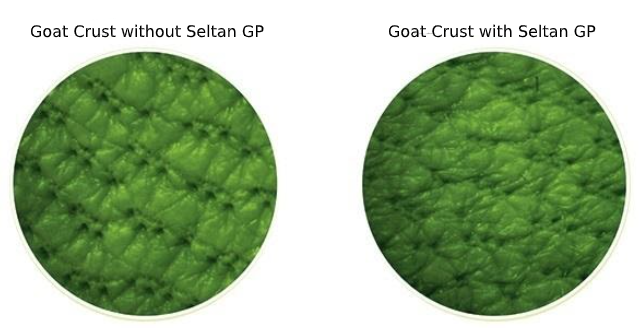

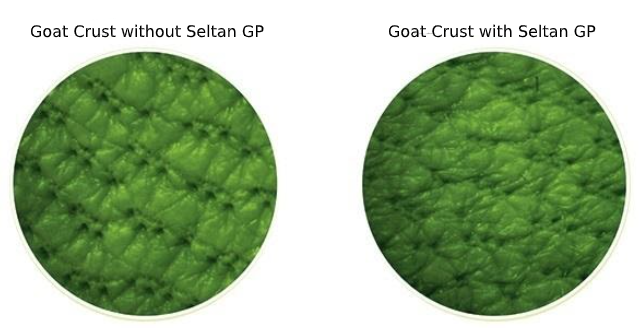

Seltan GP

Amphoteric syntan suitable for upgrading all types of softy & natural milled leather

* Based on Microscopic Laboratory Analysis Report

* Based on Microscopic Laboratory Analysis Report

Seltan GP 30

Amphoteric Syntan suitable for upgrading all types of upper, nubuck & suede leather.

Seltan PG

Amphoteric syntan suitable for upgrading upholstery leathers.

Seltan AK

Amphoteric syntan suitable for increasing the dye intensity & burnish in all types of leather. It is a partial replacement for vegetable tannins

Seltan GN

Speciality neutralising agent for not exceeding pH 4.8 with uniform cross-section on all types of leather.

Seltan GT

Eco-friendly syntan for selective filling & uniform grain tightening effect on all types of leather in retanning system.

Selcomfill MK 5717 | MK 5718

Selcomfill MK 6909 | MK 6908

Cationic Natural Wet End Filler for all types softies and milled leather. It is used to produce upgraded, soft, tight and fine grain leathers with pleasant satin touch

Selcomfill BK 9009 | BK 3191

Cationic Natural Wet End Filler for all types burnish and high shine leathers.

Good upgradation, excellent burnishability and repolishability.

Improved version of Black / White pigmented wet-end fillers available

Selfix

Cationic dye fixative specially developed to improve fastness characteristics, by enhanced chemical fixation

Practical Values of our Wet End Upgradation Prodcuts

- Lower selection is upgraded to higher selection resulting in higher unit value realization

- No need to load the grain in finishing, aniline look of finished leather is preserved even in the lower selections

- It takes only 30 minutes running time

- Diminishes the visibility of vein marks, growth marks, drawn grain, grain off, scratches and pin holes

- Increase in thickness (plumpness) of the leather

- Imparts a fine and uniform grain with pleasant silky touch throughout the leather

- Marginal increase in the area of leather

- If there is no rejection, no dead stock is a great relief for the tanners.

- One can easily produce saleable quality full grain leathers out of available lower selection